rockwell hardness test precautions|rockwell hardness tester chart : exporting 1) At least two preliminary tests should be performed before beginning any measuring, in order to acclimatize the indenter, raising/lowering screw, and specimen platform. This is necessary at .

Resultado da 20 de out. de 2023 · Prognósticos UFC 294: Makhachev vs. Volkanovski O combate principal do UFC 294, que acontecerá na Etihad Arena, em Abu .

{plog:ftitle_list}

webSegundo o Reclame Aqui, o site ultrafarma.com.br é um site confiável e que entrega uma boa experiência de compra para seus consumidores. A reputação do site na plataforma é .

rockwell hardness testing procedure pdf

In addition to the various precautions used when using a variety of hardness, there are some common issues that should be noted as follows:PRECAUTIONS: For testing cylindrical test specimen, use V-type platform. Calibrate the machine occasionally using standard test blocks.

usp compressed gas and dry air system testing

January 1, 2001. Author (s) Samuel R. Low III. Abstract. The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the .al testing information. As a rule of thumb, using the heaviest load that the material can withstand is advisable as the larger indent will provide the greatest integrity and be minimally affected by . If you are interested in obtaining a complete understanding and holistic background of the Rockwell hardness test, we recommend diving deeper into the ASTM E18-20 Standard Test Methods for Rockwell Hardness and .

1) At least two preliminary tests should be performed before beginning any measuring, in order to acclimatize the indenter, raising/lowering screw, and specimen platform. This is necessary at . It is critical to keep the exterior finish clean and decarburization from heat treatment ought to be taken off. Unique Cases. While Rockwell hardness testing can be used on a wide range of samples, there are certain .

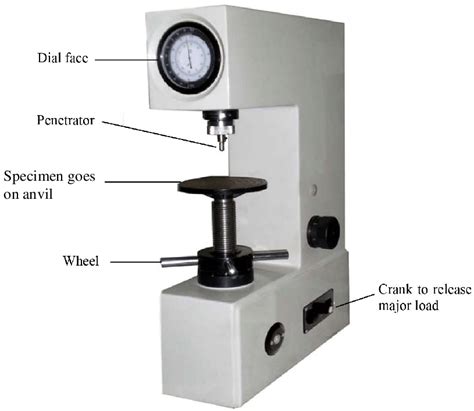

The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell .The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .Safety Hazards and Precautions. Stanley (the Rockwell hardness tester) is a relatively safe machine. Try to resist hardness testing your body parts or the body parts of bystanders. .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. We depend on the data produced to verify heat treatment, structural .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload . Rockwell Hardness Test. The Rockwell hardness test is a widely used method for determining material hardness, especially in high-volume testing environments, due to its speed, simplicity, and efficiency. It provides direct hardness readings without the need for additional calculations, making it ideal for routine quality control.

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below). The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was created to determine the hardness and strength of materials. After executing the Rockwell hardness test, you will be able .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

1. To perform a calibration of a Rockwell hardness tester using a standard test block; and . 2. To measure the Rockwell hardness of a steel reinforcing bar, a widely used construction material. (b) Learning Goals: 1. To be able to perform Rockwell hardness testing, a prominent techniqueRockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .Safety Hazards and Precautions Stanley (the Rockwell hardness tester) is a relatively safe machine. Try to resist hardness testing . One interesting aspect of the Rockwell hardness test is the multitude of scales by which hardness is measured (Figure 2). Over time, many different types of indenters have been used for Rockwell .

Best Practices for Rockwell Hardness Testing Hardness Testing Basics Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 years. As a material property, its value and importance cannot be understated; the informationThe Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article. Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. We depend on the data produced to verify heat treatment, structural .Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .Equipment: Buehler Rockwell Hardness Tester Location: 3362 Hoover Hall Access: Open for undergraduate coursework Contact: Zhongyuan Qian Test Precaution 1) At least two preliminary tests should be performed before beginning any measuring, in order to acclimatize the indenter, raising/lowering screw, and specimen platform. .This hardness testing method involved the measurement of the increment of depth of an indenter forced into the metal by a primary and a secondary load. Based on Ludwig’s principles, Stanley P. Rockwell invented the Rockwell hardness test in 1919 (Rockwell 1922). Today, it is the most widely used method to determine quantitatively the .

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, and the Rockwell scale is a commonly accepted value when purchasing products. Applications for Rockwell Methods The Rockwell hardness test is widely used in various industrial

3.0 TEST METHOD 3.1 ASTM E18: Rockwell Hardness Testing This tester operates according to ASTM E18 standard in all particulars. It is used by virtually every large automotive, aerospace and defense manufacturer in the nation. 3.2 Top-loading and Test Surface ReferencingA standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.

Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C scale). The load is applied for a .3.0 TEST METHOD 3.1 ASTM E18: Rockwell Hardness Testing This tester operates according to ASTM E18 standard in all particulars. It is used by virtually every large automotive, aerospace and defense manufacturer in the nation. 3.2 Top-loading and Test Surface ReferencingVerification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. We depend on the data produced to verify heat treatment, structural . Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company. Stanley P. Rockwell invented the Rockwell hardness test. As a metallurgist for a large ball bearing company, he wanted a fast, nondestructive .

rockwell hardness tester procedure pdf

rockwell hardness tester manual pdf

usp compressed gas dry air system testing

rockwell hardness tester instruction manual

web6 de jan. de 2023 · Chegou a Raspadinha 7 que significa sorte e com prémio de 77 777 euros. Chega aos mediadores da Santa Casa a nova Raspadinha 7, que tem um prémio máximo muito curioso, 77 777 mil .

rockwell hardness test precautions|rockwell hardness tester chart